Select Page

Asian economies are rapidly industrializing with the utilization of new technologies. There is a growing web of interconnectedness, increasing emphasis on competitiveness, and more sustainability concerns. On the industrial front, there is a greater emphasis on productivity, calling for production using fewer resources and less manpower. To survive the competition and cater to the changing needs of society, reliance on technology is indispensable. The proper use of technology can potentially assist emerging economies to achieve leapfrog development. However, turning that potential into reality needs the appropriate directions and execution of tasks. The shifting of economic power to Asia has given the region a competitive edge. According to Klaus Schwab, Founder and Executive Chairman, World Economic Forum, “In today’s world, it is not the big fish that eats the small fish. It is the fast fish that eats the slow fish.” Emerging and disruptive technologies Emerging technologies usually represent continuous development of existing ones. They are characterized by far-reaching innovation, faster adoption, and multiple potential impacts on socioeconomic domains. Examples are 5G technology, smartphone applications in healthcare or education, etc. Disruption is occurring everywhere, especially in the Asia-Pacific. Disruptive technologies offer ground-breaking products and can alter the ways in which businesses, industries, and consumers operate. For example, applications of artificial intelligence and automation have streamlined repetitive jobs, and ride-sharing apps have made travel cheaper and easier. Disruptive technologies benefit consumers by providing cheaper or free, more sophisticated goods and services. They potentially result in tangible improvements in the quality of life, health, and the environment. According to a Cognizant Insights estimate, by 2025 disruptive technologies are expected to result in GDP growth of 20% to 30% in India, 30% in Southeast Asia alone, and up to 22% in PR China. What is Industry 4.0? Industry 4.0 is commonly referred to as the Fourth Industrial Revolution. It is characterized by the digitization of economic and production flows and focuses on interconnectivity, automation, and real-time data allowing interactions among machines, products, people, and processes.

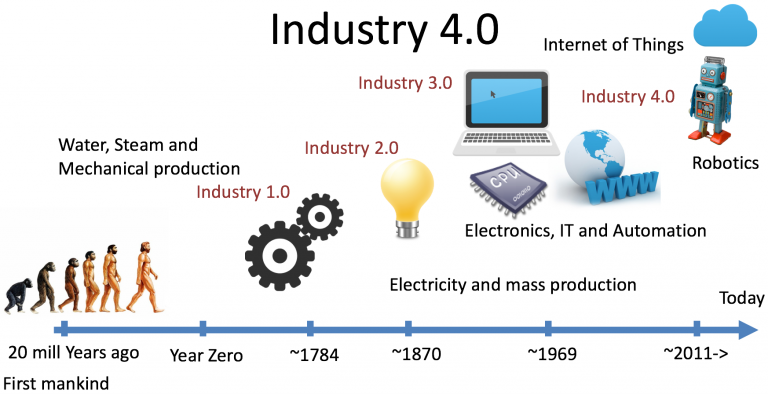

Figure 1. Evolution of Industry 4.0. Reproduced with permission from www.halvorsen.blog.

Figure 2. Nine key elements of Industry 4.0.

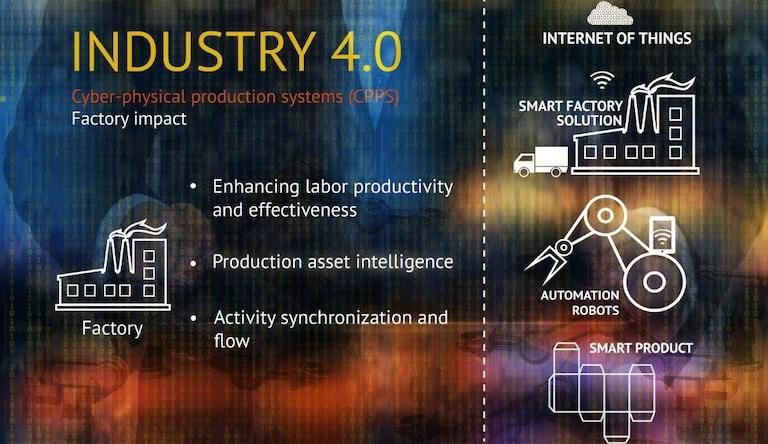

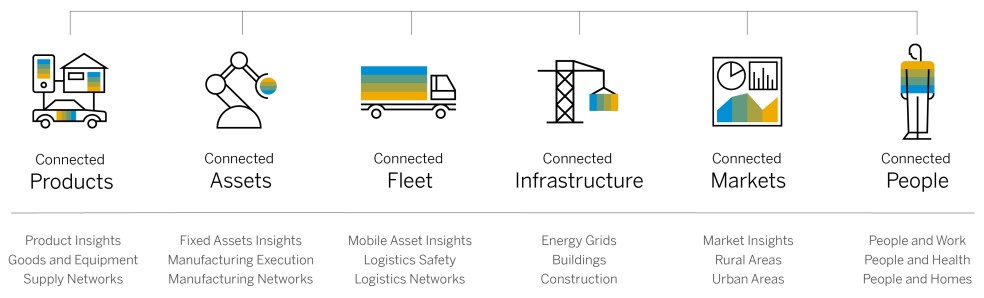

As just one example of how adopting Industry 4.0 can benefit large enterprises, part of the corporate strategy of Bosch is digitizing data and connecting plants and its customers. Industry 4.0 solutions are then tested and validated before marketing them to other companies. Customers benefit from that experience in around 280 Bosch plants. Connected solutions are boosting productivity by up to 25% at individual sites while reducing inventories by 30%. In terms of its bottom line, applications of Industry 4.0 have generated higher sales for Bosch. Figure 1 summarizes the evolutionary path leading to Industry 4.0, and Figure 2 shows its nine key elements, which are described briefly below. The Internet of Things The Internet of Things (IoT) is composed of networks of interrelated computing devices connecting objects, other devices, machines, and humans through the ability to collect and exchange data. Data can be transmitted over such networks without human-to-human or human-to-computer interactions. According to Cisco Systems, 500 billion devices are expected to be connected to the Internet by 2030. When the IoT is discussed in terms of impact on the manufacturing industry, it is referred to as the “Industrial IoT.” An everyday example of how the IoT could make life easier and safer for millions is in traffic control. Many Asian cities face severe traffic management challenges, particularly during peak commuting times. IoT applications are a potential solution.

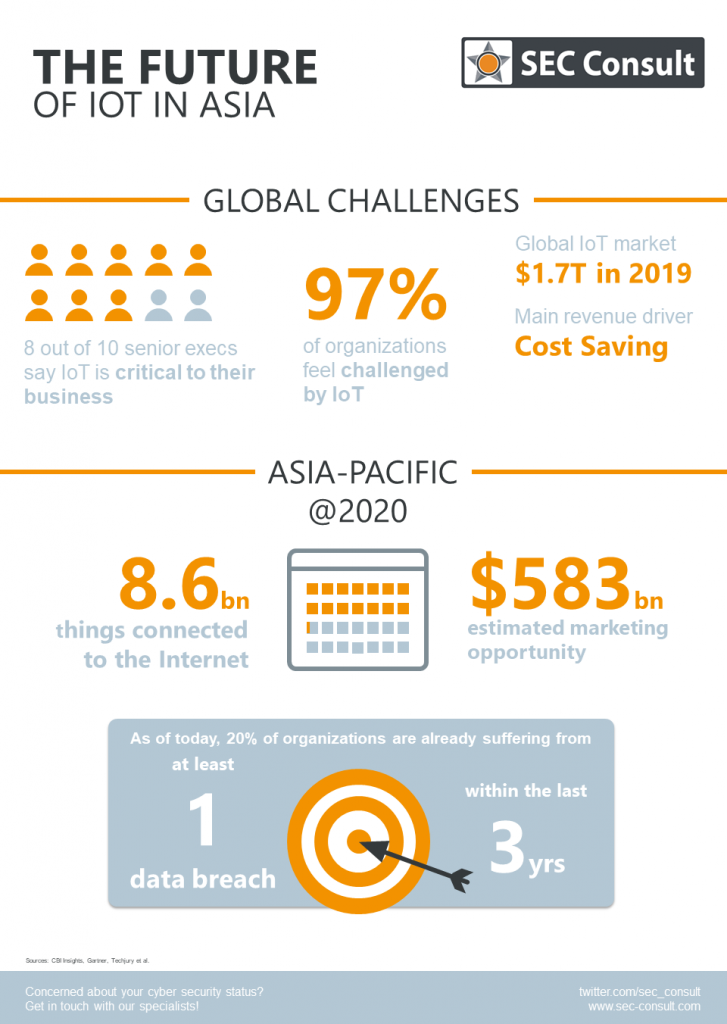

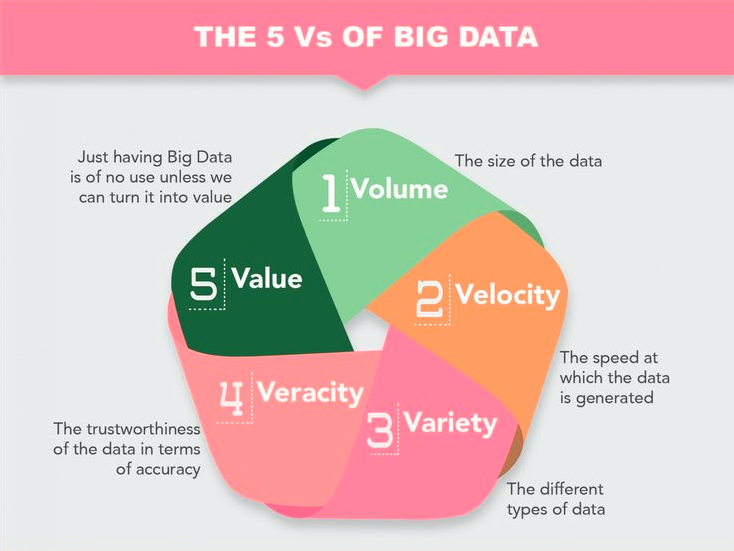

DOWNLOAD: 10 Opportunities for SME Recovery Figure 3. Future of the IoT in Asia. Reproduced with permission from sec-consult.com › blog › 2019/09 › driving-iot-growth-in-asia. Big data analytics Big data analytics are a complex process of examining large, varied datasets to uncover meaningful hidden patterns and find correlations for making informed decisions. It helps in creating strategic business value and improving efficiency, leading to better, faster, more accurate decision making. New industrial big data analytics enable manufacturers to access real-time information, forecast production needs, and adopt proactive, predictive, and prescriptive maintenance. Big data analytics are often described in terms of “the five Vs,” as shown in Figure 4.

Figure 4.

The 5 Vs of big data. Reproduced with permission from www.medium.com. Managing Director & CEO Deepu Kumar of Pro Digital Labs Private Limited, a Bangalore-based start-up, India, stated that big data analytics are finding many applications in government. The company set up a war room (within 24 hours) as an epicenter in Bangalore for Bruhat Bengaluru Mahanagara Palike (BBMP), Government of Karnataka, where a team of technologists, healthcare professionals, bureaucrats, and politicians can sit together and strategize action plans to fight COVID-19. They handle big data on contact tracing using GPS, GIS, the IoT, and surveillance technologies to identify COVID-19 cases and prevent disease spread. People with a travel history and suspected of infection can be located geographically, and healthcare solutions can be deployed in those places. Interactive web maps, story maps, and dashboard apps are used to analyze and communicate in real time. By using big data, users will always have the relevant information at their fingertips for data-driven decisions. The war room aids professionals in tracking inventory like ventilator and hospital bed availability, as well as infrastructure availability like testing facilities, quarantine facilities, and hospitals. Augmented reality Augmented reality (AR) brings digital elements to life. This is achieved via smartphone video camera functions popular among gamers and other leisure-activity users. In manufacturing, AR wearables and other devices offer operators real-time information and assist them in making faster decisions to improve work processes. AR can also transform how the military, police, and emergency services conduct training, use data, and provide services. Companies like Google are changing the way students learn by offering amazing AR-based educational experiences. System integration Going forward, integrating all the elements that make up Industry 4.0 will be the key to full-fledged adoption. Means available for network connection define the scalable potential for companies. The problem of systems working in silos can only be overcome by creating seamless connections among all partners (suppliers, manufacturers, customers, aggregators, and others) in supply chains. Complete system integration also creates transparency and increases agility. Autonomous robots Robotic automation has taken over many tasks that are dangerous for humans to perform. Now collaborative robots are increasingly moving out of their “cages” to work alongside counterpart human operators. Such robots are referred to as “cobotics” and not only interact with one another but also with people. They will eventually acquire the ability to learn from humans and self-correct. Hitachi’s ongoing efforts to develop autonomous, collaborative robotics aim to achieve manufacturing synergy among diverse types of robots and between robots and people. Cloud computing “Cloud computing” refers to the on-demand availability of resources like hardware, software, data storage, and computing power. Internet-based data centers are widely available, and steadily increasing numbers of business transactions are creating voluminous amounts of data generated from multiple internal and external sources. Those operating processes require data sharing among companies and sites. According to GlobalData’s market opportunity forecasts model, public and private computing services will account for approximately 80% of the overall USD256 billion in cloud computing revenues in the Asia-Pacific region by 2023. Simulation Industry 4.0 benefits from 3D simulations during product development and production processes. They help by incorporating real-time data to mirror physical-world attributes in a virtual-world manner. For example, shopfloor operators are able to test and optimize machine settings for the next product batch before actual manufacturing starts. According to a report published in Market Research Future, the global automotive simulation market is expected to increase by 10% in compound annual growth rate terms by 2023. Additive manufacturing (3D printing) Additive manufacturing, commonly known as 3D printing, is a transformative approach to production enabling the creation of stronger, lighter parts and systems. Instead of traditional subtractive manufacturing methods in which parts and components are formed by cutting from larger sections of material, additive manufacturing combines materials to make objects from 3D model data. These technologies offer high performance in manufacturing small batches of customized products. The advantages of additive manufacturing/3D printing technology are reductions in material waste, production steps required, and separate parts needed for final product assembly. Customization is a continuing trend in the automotive industry. Ford and other auto manufacturers are taking advantage of additive manufacturing to offer customers more vehicle options chosen from a varied palette of 3D printed parts. Cybersecurity With communication protocols and network connectivity becoming the norm in diverse fields, safeguarding information and systems from cyberattacks/cybercrimes is critical. Sophisticated tools are being used to communicate reliably, but this also requires addressing evolving risks related to the IoT, cryptojacking, insider threats, and private–public partnerships. Smart factories and Industry 4.0 The foundation of Industry 4.0 is smart factories (Figure 5). These are highly digitized premises with interconnected production facilities. They rely on the smart manufacturing techniques and technologies made possible by Industry 4.0, while at the same time contributing to its practical evolution. Responsiveness, adaptability, and agility are key features. Smart factories can operate autonomously, learn and adapt in real time, and have the ability to self-correct. According to a 2019 forecast by AmericaNewsHour, the smart manufacturing market is expected to grow at an annual rate of 15.75% during the 2018–23 period.  Figure 5. Components of smart factories. Reproduced with permission from SAP. How Industry 4.0 will affect productivity, the world of work, and employment According to an ILO report titled ASEAN in Transformation, half of salaried workers, i.e., approximately 137 million individuals, in Cambodia, Indonesia, the Philippines, Thailand, and Vietnam might lose their jobs in the next 20 years. While the adoption of Industry 4.0 may not be 100% responsible for those potential job losses, it will obviously have profound effects on global productivity, work, and employment, as illustrated in Figures 6, 7, and 8, respectively.

Figure 5. Components of smart factories. Reproduced with permission from SAP. How Industry 4.0 will affect productivity, the world of work, and employment According to an ILO report titled ASEAN in Transformation, half of salaried workers, i.e., approximately 137 million individuals, in Cambodia, Indonesia, the Philippines, Thailand, and Vietnam might lose their jobs in the next 20 years. While the adoption of Industry 4.0 may not be 100% responsible for those potential job losses, it will obviously have profound effects on global productivity, work, and employment, as illustrated in Figures 6, 7, and 8, respectively.  Figure 6. Industry 4.0 effects on productivity.

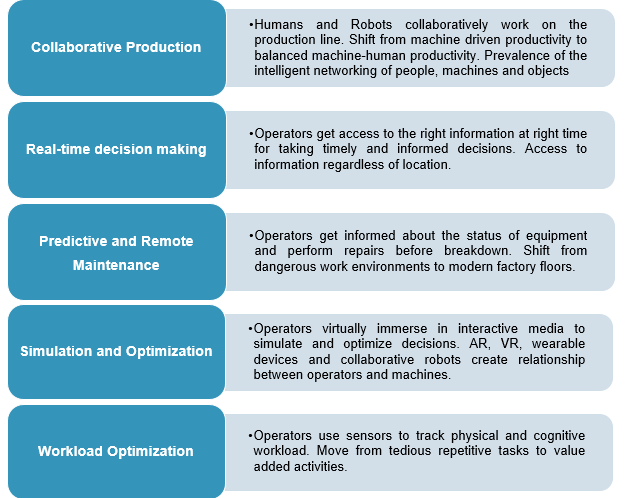

Figure 6. Industry 4.0 effects on productivity.  Figure 7. Industry 4.0 effects on work.

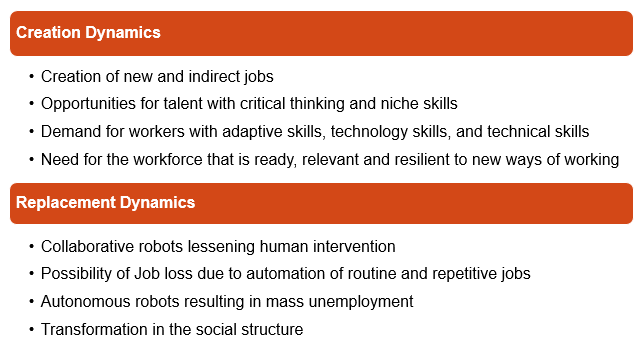

Figure 7. Industry 4.0 effects on work.  Figure 8. Industry 4.0 effects on employment. Cross-cutting challenges in Industry 4.0 adoption Some of the cross-cutting challenges faced by individuals, industries, and governments as Industry 4.0 becomes the norm can be summarized as follows: Technologies are complex to learn, understand, and adopt. Workforce willingness to change, learn, upskill, and reskill is necessary. Access to capital is required for investment. Underutilization and lack of utilization of data may be an issue. Data privacy and data piracy issues should be addressed. Build digital capabilities among people. Technological obsolescence occurs rapidly. Strong, unified leadership guiding behavioral change is a must. Policy frameworks and regulatory compliance measures should be in place. Underlying infrastructure must be available. Embrace “agile governance.” Industry 4.0 action plans for businesses and governments As Facebook co-founder Chris Hughes notably said, “You can have the best technology in the world, but if you don’t have a community who wants to use it and who are excited about it, then it has no purpose.” To take full advantage of the many benefits from adopting Industry 4.0, businesses and governments must have action plans in place to prepare citizens for change, cope with its socioeconomic requirements, and mitigate difficulties that may arise. It is recommended that such action plans take the following aspects into account to inspire communities of Industry 4.0 practice and excite citizens about its potential: Accept the fact that there is a need for change. Take small steps at a time. Focus on boosting education. Prioritize investments in reskilling and upskilling the workforce. Be process oriented instead of function oriented. Reengineer and digitize business processes. Educate stakeholders to create changes in behavior. Develop Industry 4.0-favorable government policies and support measures. Offer leadership to drive the transformation agenda.

Figure 8. Industry 4.0 effects on employment. Cross-cutting challenges in Industry 4.0 adoption Some of the cross-cutting challenges faced by individuals, industries, and governments as Industry 4.0 becomes the norm can be summarized as follows: Technologies are complex to learn, understand, and adopt. Workforce willingness to change, learn, upskill, and reskill is necessary. Access to capital is required for investment. Underutilization and lack of utilization of data may be an issue. Data privacy and data piracy issues should be addressed. Build digital capabilities among people. Technological obsolescence occurs rapidly. Strong, unified leadership guiding behavioral change is a must. Policy frameworks and regulatory compliance measures should be in place. Underlying infrastructure must be available. Embrace “agile governance.” Industry 4.0 action plans for businesses and governments As Facebook co-founder Chris Hughes notably said, “You can have the best technology in the world, but if you don’t have a community who wants to use it and who are excited about it, then it has no purpose.” To take full advantage of the many benefits from adopting Industry 4.0, businesses and governments must have action plans in place to prepare citizens for change, cope with its socioeconomic requirements, and mitigate difficulties that may arise. It is recommended that such action plans take the following aspects into account to inspire communities of Industry 4.0 practice and excite citizens about its potential: Accept the fact that there is a need for change. Take small steps at a time. Focus on boosting education. Prioritize investments in reskilling and upskilling the workforce. Be process oriented instead of function oriented. Reengineer and digitize business processes. Educate stakeholders to create changes in behavior. Develop Industry 4.0-favorable government policies and support measures. Offer leadership to drive the transformation agenda.

Dr. B.M. Avinash is an Assistant Professor in Lean Operations and Systems at the School of Business and Management, CHRIST (Deemed to be University), Bangalore, India. He holds an MBA and a PhD in Big Data Analytics and has experience in industry, academics, research, and consulting in India and abroad. His areas of work include digital transformation, disruptive technologies, Industry 4.0, blockchain technology applications, and human capital. He also serves as an international resource speaker at conferences and forums.

Dr. B.M. Avinash is an Assistant Professor in Lean Operations and Systems at the School of Business and Management, CHRIST (Deemed to be University), Bangalore, India. He holds an MBA and a PhD in Big Data Analytics and has experience in industry, academics, research, and consulting in India and abroad. His areas of work include digital transformation, disruptive technologies, Industry 4.0, blockchain technology applications, and human capital. He also serves as an international resource speaker at conferences and forums.